VOC Emissions from Cleanroom Materials

By Markus Keller

In addition to particle generation due to mechanical stress, the outgassing behavior of materials considered suitable for use in cleantooms is becoming an increasingly important factor. First, the quantities of substances emitted from the materials deemed suitable may not exceed statutory maximal allowable workplace concentrations (MAC values). Second, sensitive manufacturing environments require a controlled low leve of molecular organic contamination in the ambient air. ISO 14644-81 defines airborne molecular contamination (AMC) as the presence in the atmosphere of molecular (chemical, non-particulate) substances in the gaseous or vapor state that may have a deleterious effect on the product, process or equipment in the cleanroom or controlled environtment. According to ISO 14644-8, AMCs can be categorized in the following substance groups:

Acids (ac)

Bases (ba)

Biotoxin (bt)

Condensable contaminants (cd)

Corrosive contaminants (cr)

Volatile organic compounds (or)

Dopants (dp)

Other definitions

Organic compounds outgassed from materials (Softeners, solvents, and other volatile constituens of materials) play a vital role regarding the amount of airborne organic contamination contained in a room or in process air.

Various damage scenarios are possible. Airborne organic contamination (volatile organic compounds (VOCs) as described in ISO 16000-6)2 could settle on the lenses of lithographic units and significantly impair their performance. In the semiconductor industry, organophosphates or doping substances condensing on wafers could severely damage them. Siloxanes could lead to the complete failure of electric contacts. Therefore, sorne classes of compounds are considered to be especially critica! and may not be contained in the cleanroom atmosphere of a semiconductor factory above the current detection limit. Such compounds include siloxanes, phthalates, amines, organophosphates, doping materials, and other dangerous process-specific substances.

These substances require particular attention when considering the outgassing behavior of cleanroom-suitable materials. The material classification presented in this article enables materials to be selected for use in VOC-controlled clean manufacturing environments.

VOC-EMISSIONS FROM CLEANROOM MATERIALS

The method described permits different materials to be compared with one another from the point of view of emitting volatile organic compounds and allows them to be ranked in a list to facilitate the selection and classification of materials. The quantity of organic compounds outgassed from materials is dependent upon surface area, outgassing time, age, and test temperature. The surface-specific emission rate (SER) is related to such parameters and is expressed as mass per surface area x time [g/m2s] at the corresponding temperature. In order to have a standardized comparable test procedure, measurements are carried out in an emission chamber in accordance to ISO 16000-9. 3 Outgassing is determined by collecting and concentrating the volatile compounds and subsequently analyzing them by way of thermodesorption with coupled gas chromatography and mass spectrometry (TDGC/MS).

SAMPLE PREPARATION

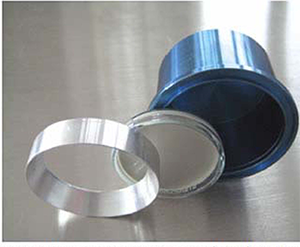

Samples have to be typical as far as their geometry and surface characteristics are concerned and need to be tested under the same conditions as those experienced by the material in the cleanroom. In multiple layer applications, layer composition must correspond to the planned usage. The cut edges of solid samples, which should not be considered as being part of the active surface area, need to be covered appropriately. VOC free carrier materials (glass dishes, stainless steel) are to be used for free-flowing samples (greases, oils) and the active surface of the samples must be quantifiable. Reactive hardening samples need to be preconditioned over a period of 30 days under controlled climatic conditions of (23ºC+/-1 ºC and 45% relative humidity (See also VDI 2083 Part 9.15 and ISO 16000- 11).4 Samples may not become contaminated during storage. This is achieved by storing the samples in a VOC-reduced mini-environment (Figure 1).

Figure 1: Representative reactive material sample in a Petri dish cast with a sampling chamber and overlying ring for determining the specific emission rate of material sample. M+W Products GmbH, Stuttgart, Germany

MEASUREMENT AND ANALYSIS

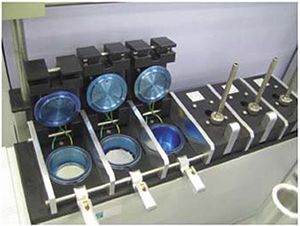

The material sample with a defined surface area is then placed in a micro test chamber (Figure 2) at atmospheric pressure at a standardized temperature of 23 ºC +/-1 ºC. After an equilibration time of 5 min, the VOC sampling time is set to one hour. A flow rate of the rinsing gas (nitrogen 5.0) of 100 mL/min is required for the micro-chamber measurements. The rinsing gas transports the volatile organic compounds emitted from the material sample to a sorption tube containing as appropriate adsorbent Tenax GR (Markes International) where they are absorbed (purge and trap method).The sampling time and flow rate form the basis of the subsequent quantitative classification. Samples can only be compared if sampling temperatures and times are identical. Sorption tubes are analyzed using TD-GC/MS in compliance with the method described in the guideline VDA 278.6

Figure 2: Material samples in micro-chamber with cover lid opened and closed. μCTE, Markos International, U.K

MATERIAL CLASSIFICATION

The emission test initially only gives the mass of all detected and quantified volatile organic compounds absorbed by the sorption tube (mVOC). The mass is then related to the surface area of the sample A and the sampling time t in arder to enable the surface specific emission rate of the material (SER) to be calculated (Equation 1).

As a theoretical model, the normalized TVOC-concentration in a reference room of 1 m3 exactly one second after insertion of the material sample with an active surface area of m2 is calculated using Equation 2.

The value TVOCnorm is then logarithmized in a decadal way to obtain the material-specific normed AMCm class (or) using Equation 3.

The described standardized material classification results in an easy-to-use comparable and communicable classification number. Due to its logarithmic nature, the whole outgassing spectra from metallic compounds up to high VOC-emitting materials can be expressed the AMCm clss N (or) is expressed as follows according to ISO 14644-8: value lies between O and -12 (Table 1). Interim classification values may also be stated. In the process, 0.1 is the lowest permissible increment of N. The term "or" defines the volatile organic compounds as a contaminant group. The classification procedure can be done for all other AMC contaminant groups as well, as long as the contaminant group is marked. The material classification enables the user a fast and effective material selection according to the needs for the later application.

- 0 100 106 (1 000 000) 109 (1 000 000 000)

- -1 10-1 105 (100 000) 108 (100 000 000)

- -2 10-2 104 (10 000) 107 (10 000 000)

- -3 10-3 103 (1000) 106 (1 000 000)

- -4 10-4 102 (100) 105 (100 000)

- -5 10-5 101 (10) 104 (10 000)

- -6 10-6 100 (1) 103 (1 000)

- -7 10-7 10-1 (0,1) 102 (100)

- -8 10-8 10-2 (0,01) 101 (10)

- -9 10-9 10-3 (0,001) 100 (1)

- -10 10-10 10-4 (0,0001) 10-1 (0,1)

- -11 10-11 10-5 (0,000 01) 10-2 (0,01)

- -12 10-12 10-6 (0,000 001) 10-3 (0,001)

Table 1

Conclusion

The use of a suitable test chamber method and corresponding analytics enables the specific emission rate of volatile organic compounds to be determined from a material sample.Through appropriate standardization, a material class can be calculated based on this value. The standardized material classification permits a direct comparison of the tested materials to be made with regard to the emission of volatile organic compounds.

The standardized micro-test-chamber procedure7 presented in this article is implemented by the Fraunhofer IPA industrial alliance for cleanroom suitable materials (CSM) and was recently accepted as a new work item proposal at the ISO Technical committee TC 209. The tested and classified materials are awarded a corresponding CSM seal and are entered into the database belonging to the industrial alliance (see www.ipa-csm.com). The database not only enables materials to be compared directly as far as outgassing behavior is concerned but also with regard to other parameters such as resistance to chemicals, particulate abrasion, and bio-resistance. This makes it a suitable tool for selecting cleanroom-suitable materials for semiconductor and life science applications.

References

1. ISO 14644-8: Cleanrooms and associated controlled environments - Part 8: Classification of airborne molecular contamination.

2. ISO 16000-6: Determination of volatile organic compounds in indoor and test chamber air by active sampling on Tenax TA sorbent, thermal desorption and gas chromatography using MS/FID.

3. ISO 16000-9: Determination of the emission of volatile organic compounds from building products and furnishing - Emission test chamber method.

4. ISO 16000-11: Indoor air - Part 11: Determination of the emission of volatile organic compounds from building products and furnishing - Sampling, storage of samples and preparation of test specimens.

5. VDI 2083 part 9.1: Clean room technology - Compatibility with required cleanliness and surface cleanliness, Beuth Verlag, Berlin, 2006.

6. VDA 278: Thermo desorption analysis of VOC emissions for the characterization of non-metallic materials for automotive industries, VDA-QMC, Berlin, 2002.

7. VDI 2083 - part 17: Cleanroom technology - Compatibility with required cleanliness class and surface cleanliness, Beuth Verlag, Berlin, 2012.