TouchMark Surface Treatment Services Featured in ODT Article

Sam Brusco, Associate Editor 05.17.21 - OTD Magazine:

A roundtable discussion between experts in the field of orthopedic device surface modification and coating technologies and services.

Carlsbad, Calif.-based SeaSpine’s NanoMetalene surface technology, used for the company’s polyetheretherketone (PEEK) interbody implants, is a departure from its nautical naming convention. The proprietary submicron layer of pure titanium is molecularly bonded to a PEEK implant with a high-energy, low temperature process, imbuing a layer of bone-friendly titanium on the implant’s entire surface area—including endplates and graft apertures. The benefits of traditional PEEK implants are also preserved: biocompatibility, a bone-like modulus of elasticity, and excellent radiographic visibility.

Last December, SeaSpine was awarded a 510(k) clearance to describe NanoMetalene as “providing a microscopic roughened surface with nano-scale features” and amends indications for use across the 12 implant systems to which NanoMetalene previously has been applied. “…these amended indications give us the opportunity to further educate surgeons about the benefits of NanoMetalene, including how its rough micro- and nano-scale topography is designed to encourage integration,” SeaSpine president and CEO Keith Valentine told the press.

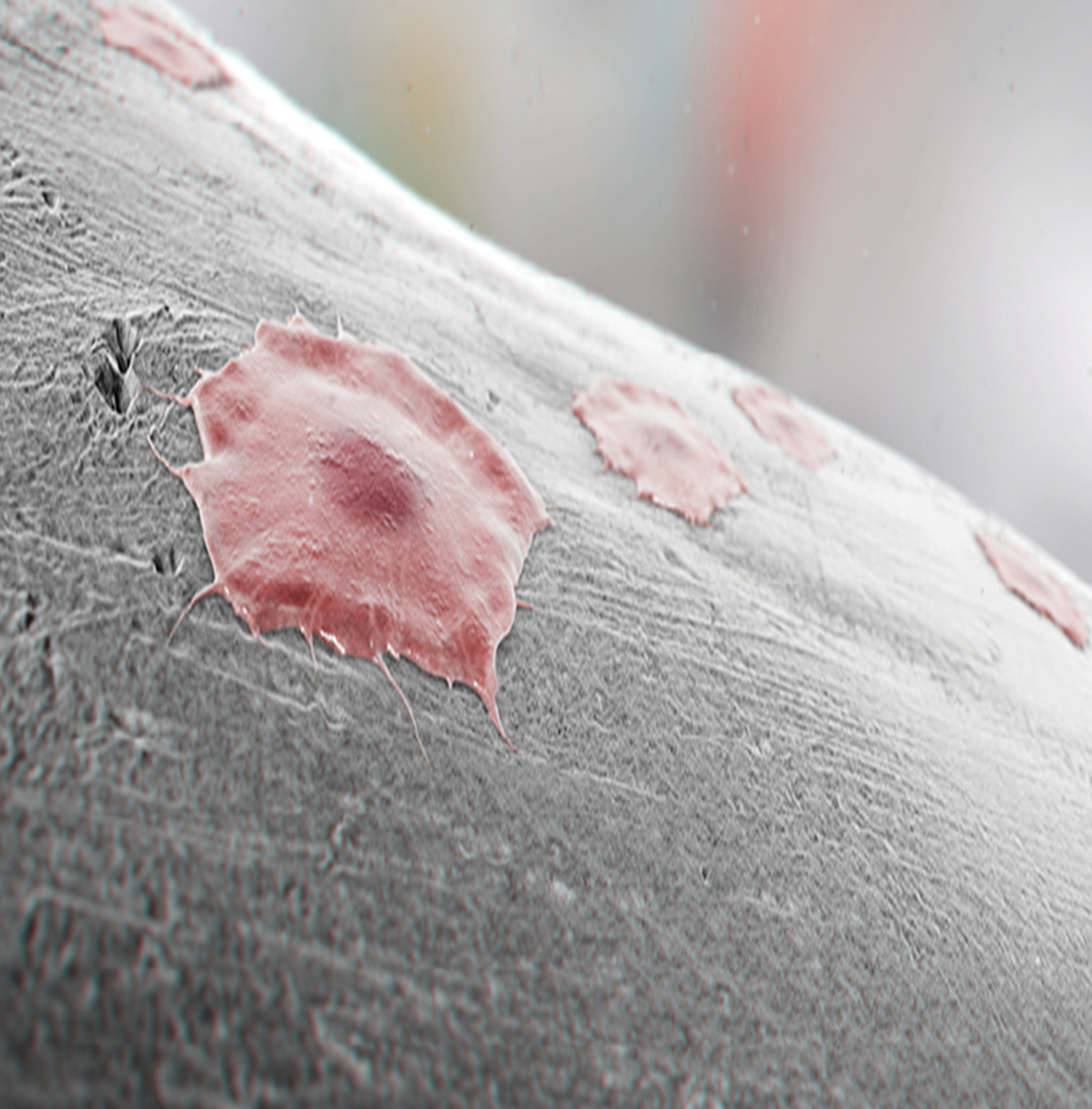

Osseointegration—formation of a direct interface between implant and bone—is much desired for orthopedic implants. Coatings like NanoMetalene and other surface treatments help enhance this property, among many others. In addition to interfacing with bone, surface treatments and coatings can help imbue orthopedic implants with antimicrobial properties, make implants more durable, assist with resistance to sterilization or corrosion, and many other enhacements.

To gain more insight on the trends and challenges affecting surface modification and coatings for orthopedic devices, ODT spoke to eight experts in the field over the past few weeks:

Ulf Brogren, chief commercial officer at Promimic AB, a Mölndal, Sweden-based provider of nano-thin surface modifications for orthopedic implants.

David Dibiasio, VP of sales and marketing at Precision Coating Company, a Woonsocket, R.I.-based provider of proprietary coatings for medical applications, including single-use devices and reusable instruments and tools.

Pat Hayes, VP of business development at Able Electropolishing, a Chicago, Ill.-based provider of electropolishing and other advanced metal improvement technologies for medical devices.

Nader Kalkhoran, VP of business and technology development at N2 Biomedical LLC, a Bedford, Mass.-based provider of highly engineered surface treatments and nanoengineered coating services to medical device OEMs.

Fred Paonessa, director of sales at Aalberts Surface Treatment, a Fairburn, Ga.-based surface technology service provider for improving material in terms of coatings and other surface technologies such as heat treatment for regional and global customers.

Eric Purviance, sales manager at TouchMark, a Hayward, Calif.-based provider of medical and electronic device pad printing.

Francesco Robotti, technology business development manager at Lincotek Medical, a global contract manufacturer that provides casting, machining, plasma spray coatings, and other technologies for the medical industry.

Kathy Siri, sales manager at Danco Anodizing, a Warsaw, Ind.-based provider of surface preparation, anodizing, and identification techniques for metal parts.

Sam Brusco:What orthopedic device trends are driving surface treatment innovations?

Ulf Brogren: Led by the developments in the spine and knee markets, there is an increasing demand for new solutions that improve osseointegration on all fronts. The aim is to create new devices that will be a more integrated part of the restoration versus simply providing mechanical support. To be able to achieve that, the surface of the implant must be able to connect and integrate with the bone.

New production technologies like 3D printing have dramatically shifted the focus from old thick coatings to new, thinner, and active surface modifications. The microporous 3D-printed implant structures can’t be combined with traditional plasma sprayed coatings, which would clog the pores and eliminate their porosity’s benefits. With our wet chemical production technology, the HAnano Surface can be applied to all materials and shapes. The unique thinness makes it possible for the first time in the industry to combine 3D-printing with a hydroxyapatite (HA) surface without clogging the pores. The first devices of this type were approved during 2020: the AxTiHA standalone ALIF and TxTiHA TLIF systems.

As younger and younger patients need joint replacement, demand for solutions with longer lifetimes grows. This drives the increasing market share of cementless knees. The need for implant surface treatments here is huge to improve bone-facing surfaces’ ability to osseointegrate.

David Dibiasio: Sterilization resistance is always at the forefront as well as better permanent marking technologies to comply with more stringent FDA and EMA European Union guidelines. Extended instrument lifecycle is also a priority, which intensified since the pandemic, where the availabile lead times for new instruments were often extended.

Pat Hayes: As orthopedic implants become increasingly sophisticated and customized, electropolishing’s ability to remove a microscopically precise and consistent layer of surface material to eliminate defects provides implant designers with the ability to explore a broad and intricate range of designs. One of our implant clients, whose orthopedic designs are created and manufactured using additive technology, recently began sending samples to determine if electropolishing will minimizing the size of intricate lattice struts while also leaving them stronger.

Nader Kalkhoran: The increased awareness of metal sensitivities to CoCr-based devices is driving growth for titanium-based orthopedic implants including shoulder, elbow, and extremities. However, untreated titanium exhibits relatively low wear resistance and is susceptible to fretting wear, leading to the need for surface treatment. Although CoCr-based implants are relatively harder material and more wear-resistant than untreated titanium, they pose the greatest risk of releasing toxic metal ions when affected by fretting corrosion. Due to this, OEMs are considering shifting to more biocompatible alternatives like titanium or ceramic material, as well as improving fretting corrosion resistance of existing CoCr devices through surface modification.

The main trend in spinal implants is toward enhancing titanium and PEEK-based interbody devices’ osseointegration and antimicrobial properties. More specifically, hierarchical texturing in the macro, micro, nano, and even meso scale in combination, as well as depositing functional coatings on the surface to enhance these properties.

Rising cleaning standards and need for improved product passivation and differentiation has increased demand for durable protective aesthetic coatings on stainless steel-based orthopedic and spinal instruments, which cannot be color anodized and protected the same way as titanium or aluminum-based devices.

Eric Purviance: The orthopedic device sector is broad and dynamic ranging from joint reconstruction, orthobiologics, trauma fixation devices, spinal devices, braces, and arthroscopic devices. Innovation in these devices requires constant evolution in the types of materials used to manufacture them—including steel, titanium, and a host of polyimides and polymers.

We specialize in high precision, permanent marking on medical devices. As the materials used to make these devices evolve, so must innovation in surface treatments to ensure high-quality markings. Treatments can be used to clean, prep, and decontaminate devices. They can also be used to alter a substrate’s surface energy to accommodate specialty prints.

Francesco Robotti: I see ortho device trends in surface treatments going in basically two directions—helping cost reduction, and helping reduce supply chain complexity. These will reduce delivery time and time to market.

There is more room to improve processes rather than an innovative material fixing unmet performances. For cost reduction, there might be a problem with metal ion release and joints components and sensitive patients. There are a certain number of solutions becoming available, those more cost effective will prevail in the long run. For supply chain complexity, match improved osseointegration performances with a number of different porous structures and materials, as well as a combination of different manufacturing steps. However, 3D printing is getting more and more appreciated and consistent to simplify under one roof from drawing to final parts.

Kathy Siri: There continues to be emphasis on devices that reduce patient recovery time, and speed to market. Our collaboration with OEMs, coupled with our robust process validation and PFMEAs, makes the surface treatment step effortless.

Brusco: How is your business responding to these macro trends?

Brogren: We have a robust research and development program to meet these new demands. We have an extensive and expanding pre-clinical data portfolio that demonstrates improved osseointegration of HAnano Surface-modified implants of varying material types and configurations. Together with customers we have also conducted several in vivo and clinical studies in compromised bone. The studies show the bone healing process is positively influenced by HAnanoSurface and implant osseointegration is significantly improved in this sub-optimal healing environment.

Dibiasio: We offer Micralox microcrystalline aluminum oxide for aggressive sterilization conditions where other oxide coatings fail. Hydrophilic coatings are optimized for antimicrobial and the best adhesion to metal substrates. We offer different model application services, not just the chemistry sales for an application but also applying hydrophilic, anodic and polymer coatings. We invested in automated technology for wire coating, instrument coating, and quality control inspection to produce the best product to the same standards every time.

Hayes: We are increasingly involved in the prototyping process as part of a “Finish First” Methodology, by which we consult with medical clients in the earliest stages to avoid design flaws that can impede finishing results. This results in metal parts that can be finished to the highest-possible quality, without flaws that can trap liquid or debris, or become initiation sites for corrosion.

Kalkhoran: We see increasing demand for our surface treatment and coating services due to the favorable trend toward vacuum-based surface modification techniques like ion implantation and physical vapor deposition (PVD) to improve performance. Since surface treatments and coatings produced these ways are often a final step in device manufacturing, the impact to existing product manufacturing lines is minimal. Surface treatment using ion implantation in particular is gaining significant attention because it can be applied to virtually all types of metal implants to enhance wear and fretting resistance as well as reduce surface friction. Ion implantation doesn’t add a surface coating and can be applied to finished devices, so it offers a safe and expedient path to gain regulatory approval for enhanced products. Our proprietary IonGuard® ion implantation-based process utilizes direct ion beam bombardment to create a hard, low friction titanium surface with a wear performance comparable to CoCr devices.

Nano-engineered metal and ceramic based coatings deposited using our Ion Beam Assisted Deposition (IBAD) technique are enhancing a wide range of surface properties, including PEEK-based spinal implant biocompatibility, metal-based orthopedic device wear and corrosion resistance, as well as stainless steel device and instrument durability/aesthetics. Our nano-engineered NanoTitanium™ coatings are currently applied to PEEK-based spinal interbody implants to enhance osseointegration, while our NanoSilver™ coatings provide antimicrobial protection for a wide range of devices, including orthopedic and cardiovascular implants. Our highly adherent NanoCeramic family of coatings are currently being considered for applications where fretting wear and corrosion—and the resulting metal ion release from the implant—pose a serious concern to health. Finally, our durable ceramic-based Spectrum aesthetic coatings are being considered for metal-based devices and instruments that can’t be color anodized—including those made of stainless steel, CoCr, and NiTi.

Purviance: We have learned to innovate to improve efficiencies. Keeping the device surface treatment function in-house is a must, and hand-off from treatment to production is key. These chambers must be flexible in size and capability. Staff must be well-versed and knowledgeable in the various materials seen, with a deep understanding and know-how to enhance a substrate to maximize adhesion or cleanliness.

Robotti: We are doing R&D and keep investing to sustain production with special processes like implant 3D printing, PVD, DLC, electrochemical treatments and coatings, and antibacterial surface treatments. We are interested in 3D printing of implants suitable for minimally invasive surgery and for high demanding fatigue strength—a lot of advances have been made on this challenge.

There is substantial interest from OEMs for electrochemical-based Brushite coatings. This material is a precursor to hydroxyapatite (HA) and shows rapid dissolution and reprecipitation to HA. Many in the spine community are exploring ways to commercialize this technology with us.

There is also concern of ion release from the CoCrMo alloy, driving exploration and commercialization of wear resistance coatings such as PVD of TiN or TiNbN. We submitted a Master File with the FDA last August. We are getting a lot of calls from OEMs in the knee and ankle space who want to offer coatings to mitigate potential ion release.

Siri: We continue to invest in R&D and partnerships, which includes our growth with Promimic’s HAnano technology. HAnano has a proven track record for enhancing osseointegration for implants in all market segments.

Brusco: How does your company’s coating technologies and/or services enhance devices used in orthopedic surgeries?

Brogren: We achieved 510(k) clearances in 2020 for both SI-joint and lumbar interbody fusion. In both of these cases, HAnano Surface supports a faster fusion process that will lead to higher success rates. The most recent 510(k) clearance in 2021 is a device for sternal closure that will improve cardiothoracic surgery success rate.

We have many new projects with a diverse and growing customer base to deliver HAnano Surface modified implants to the market. In the near future, our technology will be a part of product introductions with new substrate materials, new indications, and patient-specific designs. Additional market segments and expanded clinical applications will allow us to help the entire care chain.

Dibiasio: Our medical PTFE, an inert coating highly resistant to corrosive elements, adds exceptional lubricity where needed. The thin coating provides the needed characteristics while preserving tolerances and imbuing dielectric properties. Various formulas provide the best coating for the end use and the component’s substrate.

Our anodic coatings offer color coding in wide range of colors, and more economical substrates for lower weight and cost. Aluminum can be used in place of titanium, stainless steel, and other expensive substrates. Aluminum is easier to machine, and with the right coating performs exceptionally well. We offer embedded permanent printing in the anodic coating to provide traceability compliance and aesthetics.

Hayes: Electropolishing eliminates surface defects and contaminants left behind by the machining process and does so with microscopic precision that enables removal of surface material up to ±0.0002”. This leaves critical metal parts free of microburrs, microcracks, and other defects while also leaving parts significantly more durable and corrosion resistant. Testing shows electropolishing leaves parts with 30x greater corrosion resistance than passivation.

Kalkhoran: IonGuard® and IonGlide™ are both ion implantation-based processes applied to metallic or polymer-based devices, respectively, to affect various surface properties like wear and fretting resistance, reduced friction, improved wettability, and resistance to biofilm formation. In these processes, energetic ions of nitrogen are embedded into the substrate’s surface at low temperature to selectively modify surface properties without detrimentally affecting the implants’ bulk properties. The ion implantation process is extremely controllable and reproducible and can be tailored to modify different surfaces in desired ways. Since no coating is deposited in the process, surface enhancements are gained without the risk of delamination. Over the past 30 years, the IonGuard® treatment has been applied to millions of orthopedic implants worldwide, including those made of titanium, CoCr, and stainless steel. The IonGlide™ process, in comparison, is a milder ion treatment applied to polymer-based devices such as catheters and shunts to reduce surface tackiness or improve hydrophilicity and resistance to biofilm formation.

Our patented Mesoporous TiO2™ coating treatment enables surface texturing of titanium-coated polymer-based devices like PEEK in the meso-scale (pores with diameter in the 2-50 nm range). The treatment can be applied to both PVD and plasma-sprayed titanium coatings on PEEK. Depending on the Mesoporous treatment parameters used, the surface-modified devices will benefit from having different interferometric color appearance, which is useful for product differentiation. It also enhances their osseointegration and/or antimicrobial properties.

Purviance: We provide precise markings on medical grade polymers. Having in-house surface treatment capabilities allows us to deliver the highest quality service and customize options for a specific device application. The vast majority of devices we see are single-use tools. These tools are polymers or polyimides, mostly blends to enhance durability. These devices must be treated, printed, and turned around in a timely and cost effective fashion. Our onsite capabilities let us process the various-sized tools we see. Pad printing is still the most cost effective for the level of image transferred. Nothing maintains clarity and opacity on modular surfaces like pad printing.

Fred Paonessa: We provide biocompatible coatings meeting Class 3 requirements that include contact with skin, bone, tissue, or blood. They are approved for “non-intended implant use” on reusable and non-reusable instrumentation. These coatings can be applied to a variety of substrates including stainless steel, titanium, ceramics, and plastics.

Robotti: Thermal Plasma Spray applied on machined or forged metal parts enable the osseointegration. This can also be achieved by applying porous coating on implants made of bioinert materials like PEEK or ceramic. We offer Brushite coatings wet chemistry for additively manufactured parts. We also offer TiNbN PVD as a wear resistant/ion release blocking barrier for joint components.

Siri: Aluminum anodizing creates a durable surface that helps with instrument abrasion and corrosion resistance. Our deep image process provides exceptional wear and long life for cases and trays, saving customers money over time.

Titanium type II anodizing produces biocompatible, anti-galling, and wearresistant properties at the surface without introducing hydrogen or hydrogen embrittlement. It also adds an increase in fatigue strength of 15-20 percent. Several OEMs have tested our type II titanium to show greater performance in fatigue testing vs. other anodize suppliers in the industry. The gray color of type II is easily distinguishable from uncoated parts and implants can be masked to add colors for identification.

Brusco: What near future (within five years) orthopedic device innovations and trends do you foresee, and how do you plan to respond to them?

Brogren: We see growing interest for new surfaces with anti-microbial properties, as well as soft tissue integration. These are prioritized areas in our development programs and commercialization efforts. More and more implants will be placed in compromised bone due to the growing number of patients with diabetes, osteoporosis, and metabolic syndromes. This will create new challenges to introduce advanced implants with bioactive surfaces to better serve this growing group of patients. We are poised to partner with manufacturers across all orthopedic market segments to meet this clinical demand.

Dibiasio: Lowering cost and trimming lead times is essential, and automated processes will play a key role in the future including anodic coatings. We are an innovator in automated coating platforms, both in implementation for our coating lines and design-to-fit customer applications. Hospitals and surgeons are looking for longer life from the platforms they purchase. COVID realities exemplified the need for product that can extend life cycle should the need arise. System cycles will move out and the existing product must perform through that extended cycle and coatings are the first component with the ability to help that process.

Hayes: The growing use of and sophistication of additive manufacturing capabilities suggests the next five years will continue to bring greater innovation—particularly in implant design, where parts are getting smaller, more intricate, and more customized. We built our business around deep collaboration with engineers and designers in a broad range of industries, and we will continue to work closely with orthopedic clients to help them push the possibilities of what can be achieved.

Kalkhoran: As product developers and device designers increasingly realize many current device deficiencies can be addressed through surface modification, we should see implementation of more treatments and coatings to the next generation of orthopedic and spinal implants. Enhanced orthopedic devices with multi-functional nano-engineered coatings and treatments on existing products may provide significant performance advances with faster regulatory pathways and shorter timelines to market than designing devices with entirely new materials.

During product development, an engineer might assume they are constrained by the bulk material’s basic physical, mechanical, chemical, and aesthetic properties, but adding a coating or surface treatment can sometimes impart attributes that lie outside the range of the material’s “textbook” properties. For example, by developing the Spectrum color coatings, we have shown it possible to introduce and benefit from product differentiation on stainless steel or CoCr devices in the same way as anodized titanium or anodized aluminum products. Similarly, our NanoTitanium coatings have enabled device manufacturers to seamlessly add titanium surface biocompatibility to PEEK-based spinal implants without compromising the bulks substrate’s functional benefits of radiolucency and mechanical characteristics.

Purviance: Globally the orthopedic device market size in 2019 was $53.4 billion. Next year it’s projected to reach $62.6 billion, and reach $68.5 billion by 2027. The growth trend is daunting, presenting expansion challenges of all kinds, at all levels. From personnel to equipment, companies must be prepared in the coming years to handle demand and continued material changes, all while paying attention to cost. Those that meet the rising road ahead, will reap the rewards of increased business and helping quality of life.

Robotti: Personalization, miniaturization, price pressure, shorter delivery time, and antibacterial surface treatments. Navigated and robotic surgery, single use-disposable instruments as well.

We plan to respond by promoting advancements in 3D printing capability; enhancements in 3D printed material performances; AI SW and Big data analysis (collection to sustain process improvement); process efficiency to respond to the cost reduction trend, for example through smart quality controls, lean and fast processes inception to delivery. We are also working on non-antibiotic based anti-fouling surfaces.

Siri: We are celebrating our 50th year this year and are considered a leader for the medical and aerospace fields when it comes to surface treatments. We will continue to invest in our R&D programs to allow continued success with OEM partners.