The Importance of Machinery Safety Labels

A Matter of Risk Assessment, Liability & Compliance: Machine Safety Labeling in the 21st Century

BY GEOFFREY PECKHAM SEP 15, 2014

About the Author Geoffrey Peckham chairs both the ANSI Z535 Committee for Safety Signs and Colors and the U.S. Technical Advisory Group to ISO Technical Committee 145-Graphical Symbols. He is also a member of the U.S. Technical Advisory Group to ISO Project Committee 283—Occupational Health and Safety Management Systems. Peckham’s background includes more than two decades of experience in actively advancing safety communication. You can contact him at info@clarionsafety.com

About the Author Geoffrey Peckham chairs both the ANSI Z535 Committee for Safety Signs and Colors and the U.S. Technical Advisory Group to ISO Technical Committee 145-Graphical Symbols. He is also a member of the U.S. Technical Advisory Group to ISO Project Committee 283—Occupational Health and Safety Management Systems. Peckham’s background includes more than two decades of experience in actively advancing safety communication. You can contact him at info@clarionsafety.com

If your company manufactures machinery that has potential hazards associated with its transportation, installation, use, maintenance, decommissioning and/or disposal, you most likely have a very strong need to create effective product safety labels. This task must be done right. Simply put, the stakes are too high for this job to be done incorrectly. People’s lives and your company’s financial well- being are on the line.

From a vantage point of playing a role on standards committees in this field over the past 25 years, I’ve seen how safety labels can help or hinder those activities. While I’m not speaking for the standards committees on which I serve, I’ve noted first-hand two important outcomes:

- If properly designed, safety labels can reduce accidents dramatically. This not only improves a product’s overall safety record but adds to a company’s bottom line by reducing product liability litigation and insurance costs.

- If poorly designed, then needed safety communication does not take place, and this can lead to accidents that cause injuries. When such accidents happen, companies spend hundreds of thousands (if not millions) of dollars settling or fighting lawsuits because their products lacked adequate warnings.

There are currently several ways the antistatic characteristics of a material can be measured. Suggested procedures can be found in ESD Association Advisory ESD ADV11.2 or you may contact the ETS Independent ESD Materials Testing Laboratory for additional information.

In this article, I’ll share what I believe are some key best practices and “tools” that shape the current state-of-the-art for product safety label design. My goal is to give the machine design engineer, risk manager or in-house legal counsel some insight that will help formulate an improved safety label strategy that will better protect its products' users from harm and its company from litigation-related losses.

Tool #1: The Standards

As a manufacturer, you know that your legal obligation is to meet or exceed the most recent versions of standards related to your product at the time it is sold into the marketplace. Warning label standards are the first place you must turn when you define your product safety labels. Until 1991, there was no overarching, multiindustry standard in the U.S. (or in the world, for that matter) that gave definitive guidance on the proper formatting and content for on-product warnings. That changed nationally with the publication of the ANSI Z535.4 Standard for Product Safety Signs and Labels in 1991, and internationally with the publication of ISO 3864-2 Design Principles for Product Safety Labels in 2004. Following the design principles in these standards will give you a starting place for both the content and format choices you have to make for your products’ safety labels. Note that both of these standards are revised every five years or so, and it’s important to be aware of the nuances that would make one format more appropriate for your product than another.

Tool #2: Risk Assessment

From an engineering perspective, your job is to identify potential hazards and then determine if they need to be designed out, guarded or warned about. From a legal perspective, your job is to define what hazards are “reasonably foreseeable” and “reasonable” ways to mitigate risks associated with hazards that cannot be designed out. Here is where risk assessment comes into play.

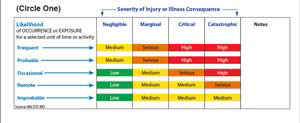

Risk Assessment Scoring Matrix

Risk Assessment Scoring MatrixIn today’s world, we should expect that a product is designed with safety in mind. The risk assessment process helps you to accomplish this task. At its most basic level, risk assessment involves considering the probability and severity of outcomes that can result from potentially hazardous situations. After identifying the potential hazards related to your product at every point in its lifecycle, you then consider various strategies to eliminate or reduce the risk of people interacting with these hazards. The best-practice risk-assessment standards that exist today (i.e., ANSI Z10, ANSI B11, ISO 31000, ISO 31010), give you a process to use to quantify and reduce risks. Using these standards as the basis

for a formalized risk assessment process not only will help you to develop better safety labels and a safer product, but it will also provide you with documentation that will help you to show the world that you are a safety-conscious company that uses the latest standards-based technology to reduce risks. This will be highly important should you be involved in product liability litigation down the road.

Tool #3: Global Warnings That Use Symbols

A large number of machinery manufacturers sell their products around the globe, and when this is the case, compliance with global standards is a requirement. The ANSI Z535.4 and ISO 3864-2 product safety label standards and the EU machinery directive, place an emphasis on using well-designed symbols on machinery safety labels so information can be conveyed across language barriers. Adding symbols also increases your labels’ noticeability. The use of symbols to convey safety is becoming commonplace worldwide and not taking advantage of this new visual language risks making your product’s safety labels obsolete and noncompliant with local, regional and international codes.

Note that sometimes symbols alone cannot convey complex safety messages. In these cases, text is often still used. When shipping to non-English speaking countries, the trend today is to translate the text into the language of the country in which the machine is sold. Digital print technology makes this solution much more cost-effective and efficient than in the past.

Conclusion

The safety labels that appear on your products are one of its most visible components. If they do not meet current standards; if they are not designed as the result of a risk assessment; and if they don’t incorporate well-designed graphical symbols, your company risks litigation and non-conformance with market requirements. Most important, you could be putting those who interact with your machinery at risk of harm. Making sure your product safety signs and labels are upto-date is an important task for every engineer responsible for a machine’s design.

I hope the above information has helped to set your company on the right path to revise its warnings.

Source: Control Design Magazine / Articles / 2014 / The Importance of Machinery Safety Labels