Silicon Carbide Materials Present Unique Shipping Requirements

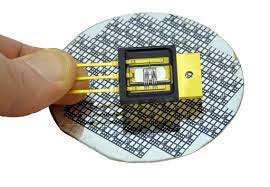

Whether shipped as processed wafers, singulated die or fully packaged modules, all

semiconductors have special transport requirements. Without the right carriers, they can easily

become damaged. Each new material and substrate type poses new handling challenges.

A prime example is compound semiconductors. Implementation of these devices is on the rise

due to their wide bandgap, which allows them to run much faster and at higher power than

traditional silicon-based ICs. One of the most widely adopted compound semiconductor

materials is silicon carbide (SiC), which has become a disruptive technology for smaller, lighter,

and more efficient power electronics devices.

According to a recent Yole Group report, the SiC device market is expected to reach $6.1

billion by 2027. With their ability to tolerate heat and voltage levels, SiC materials are being

implemented in a range of highly demanding applications, delivering the quality and reliability

vital to meeting the stringent robustness and reliability requirements of such markets as

automotive, industrial and aerospace and defense.

SiC-based sensors are vital to next-generation spacecraft. The devices’ high resistance to

temperature extremes makes them well suited for space vehicles exploring some of the solar

system’s most hostile environments. Their compact size and light weight also allow SiC power

devices to contribute to decreasing spacecraft mass while enabling faster switching speeds

and higher efficiency in power circuits.

This growing use of SiC semiconductors makes their safe packaging and delivery for

implementation in critical end products more vital than ever. However, SiC poses some

challenges. While robust, it’s typically brittle, and intact wafers full of SiC devices tend to be

heavy, making them susceptible to dropping, mishandling, and other types of damage

As manufacturers of these devices seek to eliminate yield risks and, ultimately, challenges to

bottom line profitability, inadequate handling that leads to damaged chips can be even more

costly than they may realize. In fact, the process of packaging components for safe delivery is a

key component in the industry supply chain. Packaging complex devices shipped in large

quantities is far more challenging than merely putting them in the right-sized box or adding

more padding to a package. Semiconductor carriers must be carefully designed to ensure not

only breakage-free transport but also protection from environmental hazards that devices may

encounter in transit.

Even more than traditional silicon chips, valuable SiC devices should be fully immobilized to

prevent damage from rattling or jostling during handling and transport. Delphon’s Gel-Pak

division has a long track record of collaborating with customers to develop unique solutions

for successful packing and shipping of their fragile products. Our specialty is innovating

carriers that meet your application requirements.

To learn about Gel-Pak’s storied history of product innovation and evolution, please read our

prior post titled Collaboration, the Engine that Drives Innovation

https://www.gelpak.com/blog-landing-page/collaboration-the-engine-that-drives-innovation/

For help creating the ideal transport solution for your delicate SiC devices, click here.